Cannabis Science and Technology

- July/August 2025

The Science of Cannabis Decontamination and Preservation

Key Takeaways

- Effective decontamination is vital for consumer safety and product integrity, with ozone technology and x-ray irradiation being key methods.

- Proactive measures, like microbial analysis and integrated pest management, help prevent contamination and maintain cannabis quality.

This article explores the dual challenge of cannabis decontamination and preservation, highlighting technology and best practices that protect consumers, maintain product integrity, and build trust.

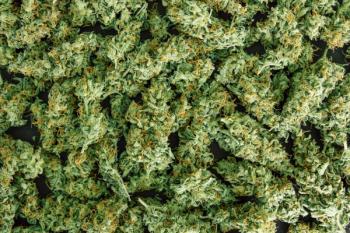

It can be a challenge to preserve the potency and remove contaminants from cannabis post-harvest, but as the cannabis industry continues to grow, it is crucial for product integrity and consumer safety. When cannabis flower is cultivated, steps need to be taken to help address any contamination the plant has come into contact with, such as heavy metals, pesticides, and microbes. However, each US state has its own specific regulations and testing guidelines, which can make or break cannabis businesses. This article delves into the intricacies of cannabis decontamination and the importance of preserving the product's integrity.

Decontamination: Addressing the Primary Challenges

“The Kill Step”

In the context of cannabis processing, a “kill step” is crucial for consumer safety. “It refers to a decontamination step used to reduce or eliminate harmful microorganisms before the product reaches consumers. Because cannabis is grown in open environments, it’s naturally exposed to microbes in the air, soil, and handling process,” said Jill Ellsworth, founder and CEO of Willow Industries. “A proper kill step helps ensure the final product is safe to consume, especially for immunocompromised users, and also helps extend shelf life by preventing microbial growth during storage and distribution.”

Preserving Product Integrity

There are a number of methods of decontamination that are effective, but not all are created equal, as some can negatively impact the overall quality of the cannabis flower, which leads us to one of the biggest challenges with cannabis decontamination. Cannabis cultivators need to provide a safe product, but decontamination has the potential to degrade the appearance, potency, and aroma of cannabis flower. Ozone technology stands out from other decontamination options due to its gentle, non-thermal, and chemical-free solution that effectively reduces pathogens without degrading the product. Ozone gas (O3) is a very reactive oxidizing molecule. The gas has the ability to destroy the “microbes’ cell wall, which enables the ozone to destroy all of the cell’s components: enzymes, proteins, DNA, and RNA (1).”The process has also been demonstrated to be effective against the range of microorganisms that state regulators would be expected to test for (2).

Maintaining the integrity of the flower may be just as important as reducing the microbial contamination. According to Carly Bader, Manager of Science at Willow Industries, ozone technology isn’t selective for specific pathogens, but the process is highly effective against many of the low-level contaminants that sneak in through everyday handling such as contact with a non-sterile surface or a gloved hand brushing a flower bud. Utilizing ozone technology, such as Willow Industry’s WillowPure, can help remove microbes like mold, yeast, bacteria, coliforms, and Aspergillus — a genus consisting of more than 300 species of mold — that can have varying degrees of virulence and a serious impact on human health (3,4). Careful control may be necessary in order to prevent significant degradation of terpenes and cannabinoids when utilizing ozone treatment for decontamination.

Another process, called x-ray irradiation, or photonic decontamination, uses high-energy photons to penetrate cannabis buds, inactivating mold spores at the DNA level. This technique is used in the medical industry, as it preserves the therapeutic properties of the product, and does not leave a chemical residue, or alter the plant’s sensory qualities (4).

Proactive Preservation

Beyond active decontamination, microbial analysis and integrated pest management (IPM) are key tools to taking a preventative, systems-based approach to cannabis quality. “It’s not just about testing the final product, it’s about routinely monitoring the entire environment: the grow room, the inputs, the materials, and the handling procedures. Each of these data points offers valuable insight into where contamination might start and how to stop it before it becomes a bigger issue,” explained Bader. “Early detection, targeted interventions, and adjustments to standard operating procedures can help cultivators avoid problems down the line.” These comprehensive management plans can contribute to the long-term preservation of cannabis quality and hopefully prevent further headaches for cannabis cultivators.

Proactive Microbial Control

Ultimately, the best tool for cannabis cultivators is to try and prevent cannabis contamination at the source.

“When you identify and address microbial risks early, whether in the grow room, during harvest, or in post-processing, you reduce the overall environmental burden on the plant,” said Bader. “By maintaining clean environments throughout the cultivation and production cycle, microbial loads stay low from the start. This minimizes the need for aggressive remediation later on, which can compromise the flower’s integrity, flavor, and potency. In short, proactive prevention helps preserve the full value of the product all the way to the consumer.”

Willow, for its part, offers a standalone, full-time air filtration system called WillowAir, which proactively decreases airborne microbial contamination in cannabis facilities. The system utilizes MERV-13 filters to capture a variety of particles such as Aspergillus spores, mold, bacteria, as well as cannabis dust as small as 0.3 microns, and holds the capacity to cover zones of up to 10,000 cubic feet (5). As the air is continuously processed through the filter, both the product and workers in the environment of the facility experience a safer growing and processing space.

Evolving Regulations and Industry Best Practices

Testing requirements are rarely implemented for long before being updated to another set of industry standards. Bader expressed that it is critical for cannabis producers to prioritize both cleanliness and quality, regardless of the current standards.

Without federal standards in place, each state is left to create its own regulations that need to be enforced. Kim Anzarut, CQA, CP-FS, the CEO and founder of Allay Consulting, explained in her August 2025 blog called “Stuck on Compliance,” that “some states conduct frequent, thorough inspections, while others take a more reactive approach, investigating only after complaints or incidents (6).” Companies that adhere to stricter requirements rather than the bare minimum will be in a better position than those that skip safety procedures, which can hurt both the company and consumers.

Ellsworth and Bader both expressed how testing standards have become more rigorous, and contamination is becoming a big concern and hot topic within the cannabis industry. Stricter pressure toward decontamination protocols may be the new wave of change within the space. Some states, such as Massachusetts, have already begun requiring decontamination labeling (7). “Another key challenge will be consumer education and transparency. Most consumers don’t fully understand what decontamination means or why it’s necessary," Ellsworth commented. "As the industry evolves, clear labeling and open communication around how a product was treated, whether through ozone, irradiation, or other methods, will empower consumers to make more informed decisions. Just like organic labeling in food, cannabis buyers will start to care how clean their flower is, and how it got that way.”

Conclusion

The evolving cannabis industry faces a significant dual challenge: ensuring consumer safety through effective decontamination while preserving the natural integrity of the product. As this article has demonstrated, microbial contamination is an inherent risk, and a reactive, post-contamination approach is often insufficient The proactive, preventative measures discussed in this article are equally vital. Ultimately, the future of the cannabis industry will be defined by its commitment to these strategies. As regulations continue to tighten and consumers become more educated, businesses that prioritize a comprehensive approach will build lasting trust.

References

- Kern, R.; Green, J. R. It’s not too late: Post-Harvest Solutions to microbial contamination issues. Cannabis Science and Technology. 2024, 2 (6)

- Brodowska, A.J. and Smigielski, K. Ozonation-an alternative decontamination method for raw plant materials, Food Sciences and Biotechnology, 2013,

http://www.bfs.p.lodz.pl . - WillowPure.

https://willowindustries.com/willowpure-systems/ (accessed Aug 13, 2025). - Smith, D. Understanding aspergillus contamination in cannabis flowers and the risks to immunocompromised individuals. Cannabis Science and Technology. 2024, 7(6), 24-30.

- WillowAir.

https://willowindustries.com/willowair/ (accessed Aug 13, 2025). - Anzarut, K. The compliance crisis: 10 emerging cannabis compliance issues in 2025. Cannabis Science and Technology. August 1, 2025,

https://www.cannabissciencetech.com/view/the-compliance-crisis-10-emerging-cannabis-compliance-issues-in-2025 (accessed 2025-08-13). - Leafly Staff. A state-by-state guide to cannabis packaging and labeling laws. Leafly. July 28, 2020.

https://www.leafly.com/news/industry/a-state-by-state-guide-to-cannabis-packaging-and-labeling-laws#massachusetts (accessed 2025-08-14).

Articles in this issue

Newsletter

Unlock the latest breakthroughs in cannabis science—subscribe now to get expert insights, research, and industry updates delivered to your inbox.