Why Packaging and Labeling Compliance Matters

Key Takeaways

- Labels are vital for marketing and compliance, impacting consumer decisions and regulatory adherence.

- Noncompliance can lead to recalls, warning letters, and reputational damage, emphasizing the need for vigilance.

Learn cannabis packaging compliance tips and label requirements to avoid costly regulatory pitfalls and enhance brand visibility.

Labels are often the very first interaction a consumer has with your product, making them a powerful tool to capture attention. A well-designed, compliant label not only communicates essential information, it also tells your brand’s story, sets you apart on the shelf, and influences buying decisions.

From colors and fonts to clear product claims and transparent ingredient lists, labels act as both a marketing asset and a compliance requirement. In many cases, the label is what draws a consumer to pick up your product in the first place, creating that crucial first impression that can convert interest into a purchase.

When it comes to food, dietary supplements, cosmetics, and pharmaceutical products, proper packaging and labeling is a must. Packaging and labeling are not just about marketing appeal, they’re about compliance, safety, and keeping you in business.

Why It Matters

State regulators and the Food and Drug Administration (FDA) require that packaging and labels clearly communicate what a product is, how to use it safely, and what risks may be involved. Noncompliance can result in warning letters, product recalls, costly re-labeling, and even reputational damage.

Costs with Re-Labeling: Companies may need to scrap thousands of noncompliant labels and pay for expedited printing of corrected versions. For products already packaged, additional labor is needed to reapply new labels or, in worst cases, destroy finished goods. Production halts to correct the issue can interrupt sales pipelines and delay launches.

Recalls: A product recall is one of the most disruptive and costly events a company can face, and labeling errors are a common trigger. Something as small as a missing allergen statement, an inaccurate net weight, or a misleading claim can force products off shelves nationwide. A recall puts your brand on the FDA’s radar, often leading to heightened scrutiny in the future. Recalled products must be collected from distributors and retailers, adding shipping, handling, and administrative expenses. Frequent or large recalls can damage relationships with retail partners who bear the burden of pulling inventory and processing returns.

Warning Letters: An FDA Warning Letter is often the first public signal that a company has run into compliance trouble. These letters are issued when the FDA identifies significant violations of the law, commonly related to misbranding, labeling errors, unapproved claims, or manufacturing practices. Unlike informal feedback from an inspection, a Warning Letter is serious: it becomes part of the public record, easily searchable on the FDA’s website, and can damage a company’s reputation overnight.

Reputational Damage: Perhaps the greatest loss is consumer confidence. Shoppers may hesitate to repurchase a product, or avoid the brand altogether, if they associate it with inaccuracy, safety concerns, or poor quality control.

The reality is that labeling compliance is not just a regulatory box to check, it’s a safeguard against financial loss and long-term reputational harm. Companies that invest in strong compliance processes upfront often save exponentially more by avoiding these costly setbacks.

Which Regulations Apply to Your Labels?

Federal Requirements

For traditional foods, dietary supplements, cosmetics, and pharmaceuticals, regulatory requirements are generally well-established, but they rarely stay static. Updates to labeling rules, ingredient declarations, or claim language can happen with little notice, often catching companies off guard. Maintaining a reliable and fully compliant label is your first line of defense. It not only ensures that your product meets current FDA standards but also minimizes the risk of enforcement actions, warning letters, or costly recalls.

A compliant label demonstrates to regulators that your company takes safety and transparency seriously, which can reduce scrutiny and help maintain smooth market access. In industries where trust and accuracy are paramount, staying ahead with correct labeling is both a compliance strategy and a competitive advantage.

State Specific Requirements

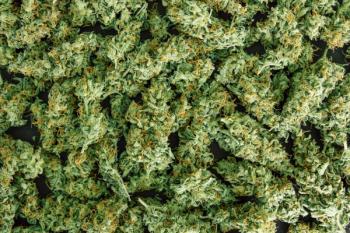

In addition to federal requirements, individual states often impose their own packaging and labeling rules, which can be even more stringent. For example, the cannabis industry faces some of the most rigorous standards, with labels typically requiring multiple warning statements, transparent testing information, potency declarations, and child-resistant packaging. It’s important to note that these requirements vary widely from state to state.

Similarly, hemp products can be subject to unique state-specific regulations. Colorado stands out with comprehensive labeling rules, which go beyond federal expectations. These include additional warning statements, detailed potency disclosures per serving and per container, and specific requirements for products containing intoxicating cannabinoids derived from hemp.

The Risk of Noncompliance

Misbranding and mislabeling are among the most common enforcement actions. Something as simple as a missing allergen declaration or misleading claim can trigger recalls, fines, and eroded consumer trust. Not to mention the cost of re-printing labels.

One of the most overlooked costs of noncompliant packaging and labeling is the expense of reprinting. If a label is found to be inaccurate, whether due to a missing allergen declaration, incorrect net weight, improper claims, or state-specific requirements not being met, the entire batch of labels may need to be discarded and reprinted. This not only creates direct financial waste in design, printing, and materials, but it can also delay product launches, interrupt supply chains, and strain retailer relationships.

For smaller businesses, these setbacks can be especially damaging, as margins are often tighter and production runs smaller. In some cases, re-labeling may even require repackaging products already filled, adding significant labor and material costs. By ensuring compliance upfront, companies can avoid costly reprints and maintain smooth, uninterrupted market access.

Packaging and Labeling Management

Effective labeling and packaging management is a critical component of regulatory compliance and operational efficiency. Keeping strict control over label and packaging inventory ensures that the correct versions are always used, prevents accidental mislabeling, and reduces the risk of distributing noncompliant products. Proper inventory management also helps track expiration dates, lot numbers, and any updates to regulatory requirements, making it easier to implement changes quickly and avoid costly recalls or reprints.

For industries with frequent regulatory updates (like food, supplements, hemp, or cannabis) robust labeling and packaging control acts as a safeguard against errors, ensures consistency across batches, and supports overall brand integrity. In short, organized management of labels and packaging isn’t just an operational necessity, it’s a strategic tool that protects both compliance and your bottom line.

The Competitive Advantage

Compliance doesn’t just keep you out of trouble, it sets your brand apart. Proper labeling builds transparency, demonstrates quality, and earns consumer confidence. Hiring a third party to review your label is a great way to double-check your work. I also recommend conducting routine internal label reviews and staying updated on FDA guidance to catch compliance issues before they become costly problems. The most successful companies understand that compliance isn’t reactive, it’s strategic. They’re already implementing the systems, documentation, and training needed to meet federal expectations. With federal legalization on the horizon, preparation will determine who thrives and who’s left behind when the rules tighten.

About the Author

Kim Anzarut, CQA, CP-FS is the CEO and founder of Allay Consulting. Direct correspondence to:

Newsletter

Unlock the latest breakthroughs in cannabis science—subscribe now to get expert insights, research, and industry updates delivered to your inbox.