Grinding Challenges: Interview with Kyle Loucks and Harrison Bard

Key Takeaways

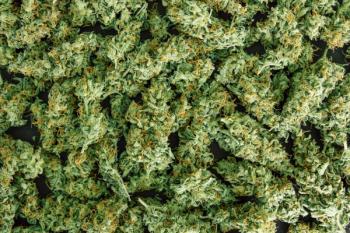

- Optimal particle size for ground cannabis is three to four millimeters to prevent clogging and uneven burning.

- Fine grind releases excess terpenes and can clog pre-rolls; coarse grind causes air pockets and canoeing.

Kyle Loucks and Harrison Bard discuss the challenges of cannabis flower grinding.

In this interview, Kyle Loucks, CEO of RollPros, and Harrison Bard, CEO and Co-Founder of Custom Cones USA and DaySavers, converse on the issues that can happen when grinding cannabis flower for pre-rolls.

Transcript:

Madeline Colli: What is the recommended particle size for ground cannabis, and what issues can arise if the grind is too fine or too coarse?

Kyle Loucks: Yeah, so if you have too fine of a grind, it can, it'll get filled with resin. I'm sure people have experienced this where you get halfway through a joint and it clogs up. That happens with too finely ground flower. Also, when you grind it finer, you're actually, you're releasing more terpenes than you need to. So, you're kind of killing that flavor that you know your consumer wants, and then too coarse of a grind you can get little pockets of air in there. That's really whatwould start a canoeing event, is if you have a pocket in there of air. It'll burn quicker. So, we usually recommend a particle size between like four and three millimeters, and then you'll always have a little bit of smaller particle in there that kind of fills in the gaps, but, that's kind of like our recommended range.

Colli: So, if you have pockets of air, you were saying, it's going to make it burn quicker?

Loucks: Yeah, and that's another one of the things that I saw with a cone is if you have, if you are filling it from the top, and you have a bigger chunk go in, there's going to be a void behind it. And so, the air flows through the path of least resistance, and it's going to hit that pocket. From there, it's going to burn your paper, and then all of a sudden, you're like on a canoe It's the canoeing issues that are prevalent in the cones is purely from how they're being made.

Colli: Yeah, not ideal.

Loucks: Yeah, exactly, yeah.

Harrison Bard: The particle size and the moisture content of the cure and the flowr is going to affect the manufacturing process as well. If your flower is too dry or in too small of a particle size, it could compact like sand into into the pre-roll, where there's no air flow. So then, as you're trying to pull through the pre-roll, and as it's burning, it's like compacted into sand with no room for the air to move through, and then you get clogs and a really unenjoyable smoking experience. If it's too large of a particle size, then typically you have an uneven particle distribution, because it's impossible to avoid, some of its turning into dust. As you grind it up, there's going to be some small particles, some big particles. So then we recommend cannabis operators to use a sifter. That sifter is going to help you take, stratify all the different particle size, and then you could choose what you want. The stuff that's too big. If there's stems in there, you throw those away. Or you could send it out to extraction and use that to make edibles, or continue to grind down the big particle size until you get what you want, and then the really small particle size, you know, maybe you want a certain percentage of that in your ground flower mix, or maybe you also send that to extraction. But if you have an uneven particle distribution, that means you're going to have some small chunks, some big chunks, some really big chunks. That's going to give you problems in the manufacturing process a couple different ways. It's going to make it really hard for you to get a consistent weight. So a lot of the times, or a lot of the ways that pre-rolls are manufactured, is with the volumetric filling, where they're looking at a certain volume and saying, "This volume should hold this amount of weight of cannabis." And it's like an assumption in a ratio of, it should hold this amount of weight. But, only if your particle size is uniform, can you trust that. Because if you have 100 holes in the metering tray that you're making your pre-rolls out of, and you have an uneven particle distribution, some of those holes are going to be filled with mostly small particles and some big particles, whereas some are going to be mostly big particles and some small particles, and those are going to hold a different amount of volume. And then therefore a different amount of weight. So if you're trying to get consistency in terms of the size and weights of your pre-rolls, that's really important. Also that can cause uneven burning. If you have a section of the pre-roll that is uneven and has some big chunks, those big chunks are going to burn slower than the smaller particles, and then you'll have an uneven burn. And then people call that canoeing or runs, and then they feel like they wasted a pre-roll. They have to keep lighting it and burn part of it off.

Newsletter

Unlock the latest breakthroughs in cannabis science—subscribe now to get expert insights, research, and industry updates delivered to your inbox.